Custom Precision CNC Machining

Five Advantages Of Products

- Tight Tolerance

- Smooth Surface

- Fast Delivery

- Good After-sales Service

- CNC Machining Processing

Product Details

Product Details

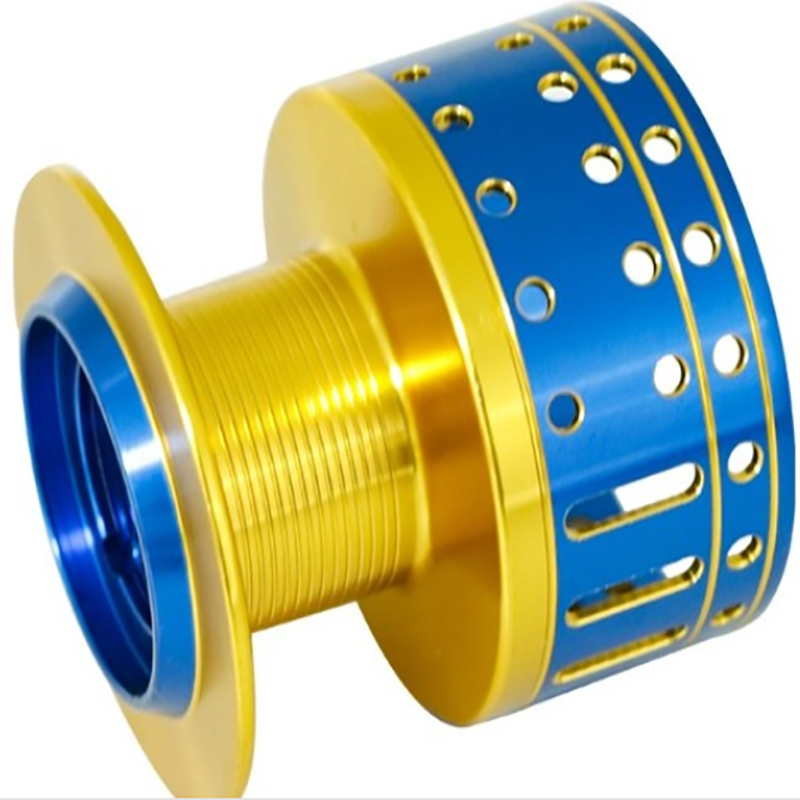

Product Name: Custom CNC Precision Machining

Material: Aluminum 6061 T6

Surface Finish: Anodizing, surface treament as customers' requirement

Dimension: Customized

Process: CNC Milling

MOQ: 1 PCS

Delivery Time: The fastest 5-7days for sample and small volume, according to the volume to determine the delivery time

Delivery Terms: DHL, FEDEX, UPS, TNT, etc.

The Advantage of Diferent Surface Finish for your CNC Machining Parts

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

Powder coating forms a durable, wear resistant and corrosion resistant layer on the surface of parts. Powder coating can be used to apply colors to parts and is compatible with any metal.

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. Most commonly applied to aluminum.

Painting the surface of a part improves its aesthetic appearance and can provide brand recognition to consumers. In addition, painting can have a protective effect on parts.

Aboout CNC Machining Process

What Is CNC Machining?

CNC machining is a subtractive manufacturing process where raw material is removed with a variety of precision cutting tools to make a part or product. Advanced software is used to control the equipment according to the specification of your 3D design. Our team of engineers and machinists program the equipment to optimize cutting time, surface finish and final tolerance to meet your specifications. We use CNC machining not only to manufacture parts and prototypes but also to make mold tools.

Advantages Of CNC Machining

CNC machining is great to meet a range of your product development needs. Here are some of the benefits of precision machining:

1. Quick removal of large amounts of metal material

2. Highly accurate and repeatable

3. Suitable for many different kinds of substrates

4. Scalable volumes from one to 100,000

5. Low investment in tooling and preparation costs

6. Economical

7. Fast turnaround

Dongguan Fifth Metal Co., Ltd.

Contact Person: Sam Zhu

Department: Engineer

Post: Project Manager

Telephone: +86 15322401809

Landline: +86 0769-86651595

Company Address: 8# 1st Road of Xiangxi Gongye, Shipai Town, Dongguan, China 523000

Factory Address: 8# 1st Road of Xiangxi Gongye, Shipai Town, Dongguan, China 523000

Website: www.fmmachining.com

Previous: OEM CNC Precision Machining

Next: Precision CNC Machining